Manufacturing:

Where Precision

Meets Scalability

Production Process

We meticulously procure materials of the highest quality that adhere to stringent aerospace standards. This ensures that our products are built with a solid foundation, guaranteeing their performance and longevity in the demanding environment of space.

Every specific part is machined with the utmost precision. Furthermore, these parts undergo specialized chemical treatments, enhancing their durability and resistance to wear and tear, essential for the harsh conditions they’ll face.

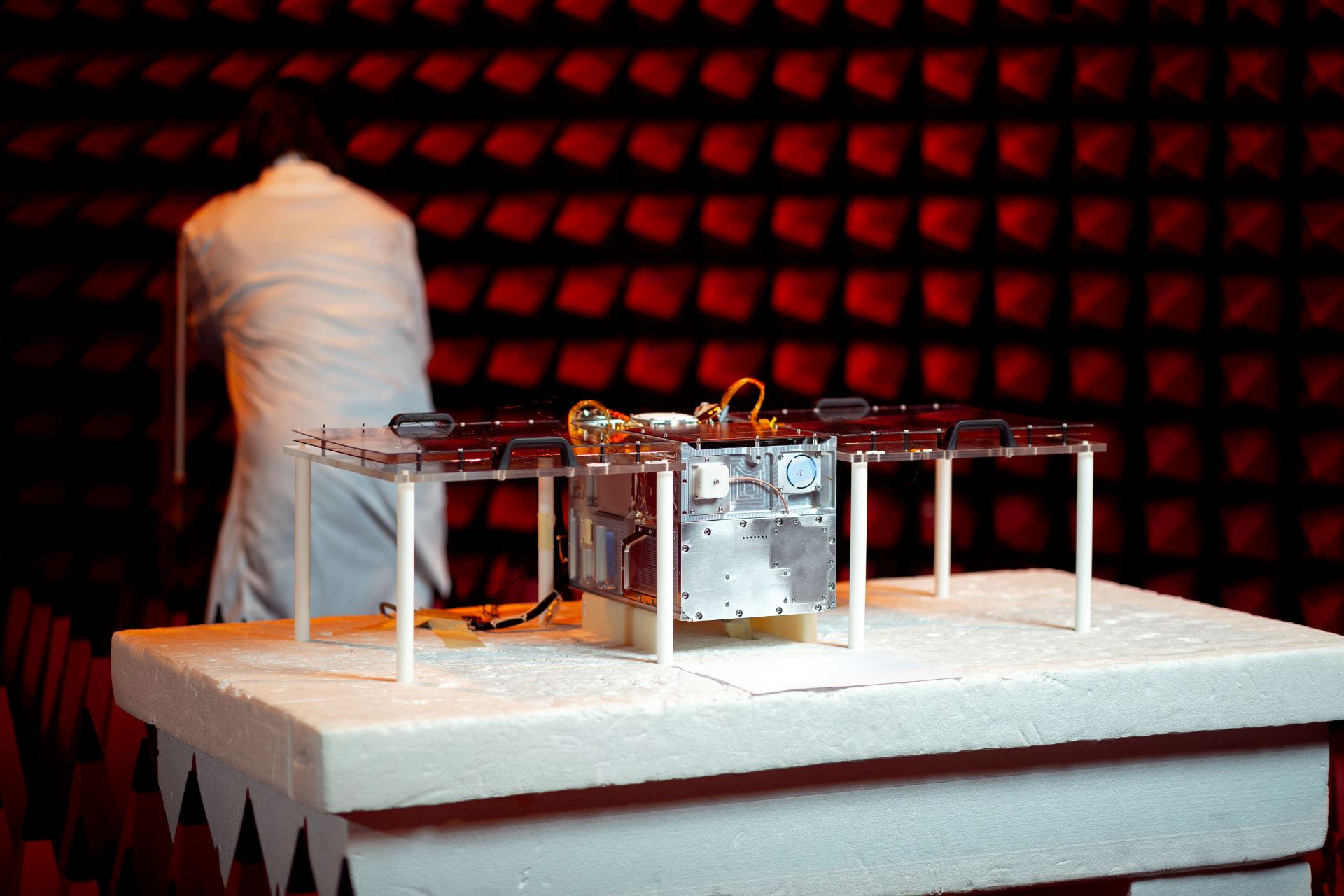

Our assembly process employs advanced techniques that ensure precision and consistency. Every component is fitted seamlessly, ensuring the overall integrity and performance of the final product.

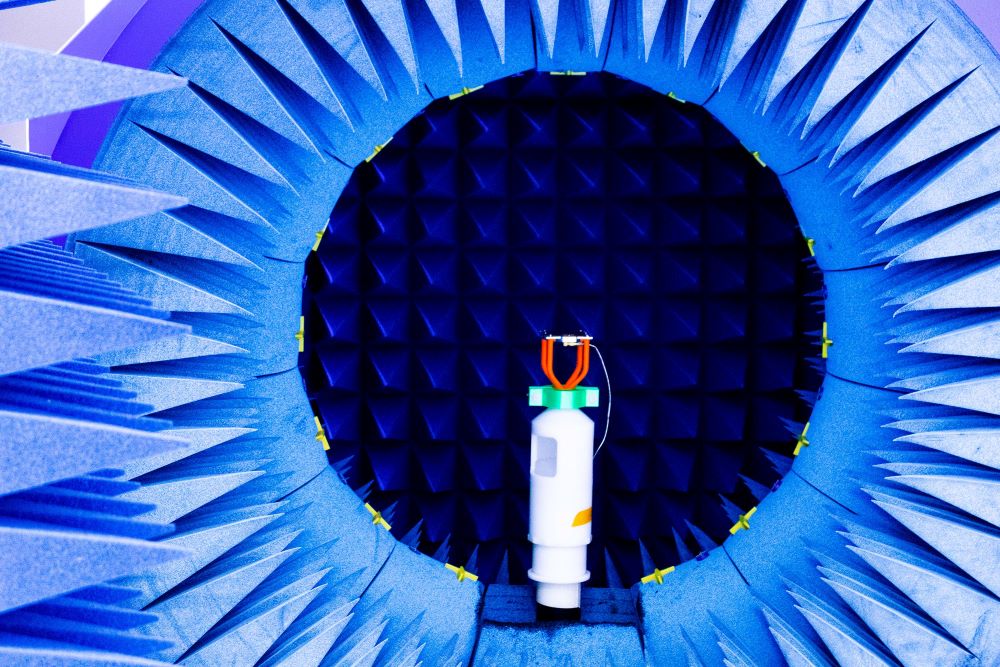

We rigorously test our products against our highest standards. This step is crucial to validate that each product operates correctly and meets our quality benchmarks.

Quality is paramount in our production. Thus, we implement rigorous quality control checks at various stages of the production process, ensuring that each product aligns with our strict criteria and is free of defects.

Once our products pass all checks, they are carefully packaged. This ensures they are shielded from physical impacts and environmental factors during transit, ensuring they reach our clients in pristine condition.

Anywaves Performance

EN9100 Certification

We are proud to hold EN9100 certification, an internationally recognized aerospace quality management system. This not only underlines our commitment to the highest quality standards but also assures our clients that our manufacturing processes are rigorously vetted for compliance with aerospace regulations.

Counterfeit Detection

Counterfeit parts can pose significant risks, particularly in aerospace applications. To mitigate this, we have implemented a robust counterfeit detection process. We source our materials exclusively from EN9100 certified suppliers and conduct rigorous inspections to ensure the authenticity and quality of all components.

Non-Conformity Management

At Anywaves, we have established protocols for identifying and managing non-conformities at each stage of the production process. This includes not just correcting the non-conformity but also analyzing root causes to implement preventive actions.

Partnering with Renowned Suppliers

All of our main suppliers hold an EN 9100 certification, the globally recognized quality management system for the aerospace industry. This ensures that every component and material that enters our facility has already met stringent quality standards.

Being based in the Toulouse Area, a hub of aerospace excellence, our suppliers are well-versed in the intricacies and demands of space technologies. This proximity allows for seamless collaboration and swift problem-solving.

Our suppliers share our focus and expertise in the field of space technology. This specialization ensures a deep understanding of the components and materials, contributing to the high quality of our end products.

Our relationship with each supplier goes beyond mere transactions. These enduring partnerships allow us to work closely on quality assurance, innovation, and process optimization

Resources

How Can We Help?

We look forward to hearing from you