Our Design Expertise

The Anywaves Design Process

In the PDR phase, the initial design concepts are analyzed and reviewed. We conduct an exhaustive state-of-the-art analysis of the current antennas concepts in order to select the most promising ones. Then, we perform preliminary designs on the chosen concepts to adjust them to our needs and estimate their performances. This crucial step allows us to identify a baseline and a back-up solutions.

This early stage ensures that the project’s objectives, requirements, and constraints are clearly identified and understood. The foundation of every antenna design is laid here, and it informs the subsequent stages of development.

During the CDR stage, the finalized design undergoes a rigorous review to ensure it meets all technical and functional specifications.

At this point, any potential issues are identified and resolved, guaranteeing that the project is ready to transition from the design phase to the prototyping stage.

The MRR is a pivotal phase conducted after the CDR, where the readiness for manufacturing is assessed. This involves evaluating the feasibility of mass-producing the antenna design, assessing material sourcing, and ensuring all subsystems are mature enough for production.

It’s the bridge between design approval and actual manufacturing, ensuring that the design is not just good on paper but is also manufacturable at scale.

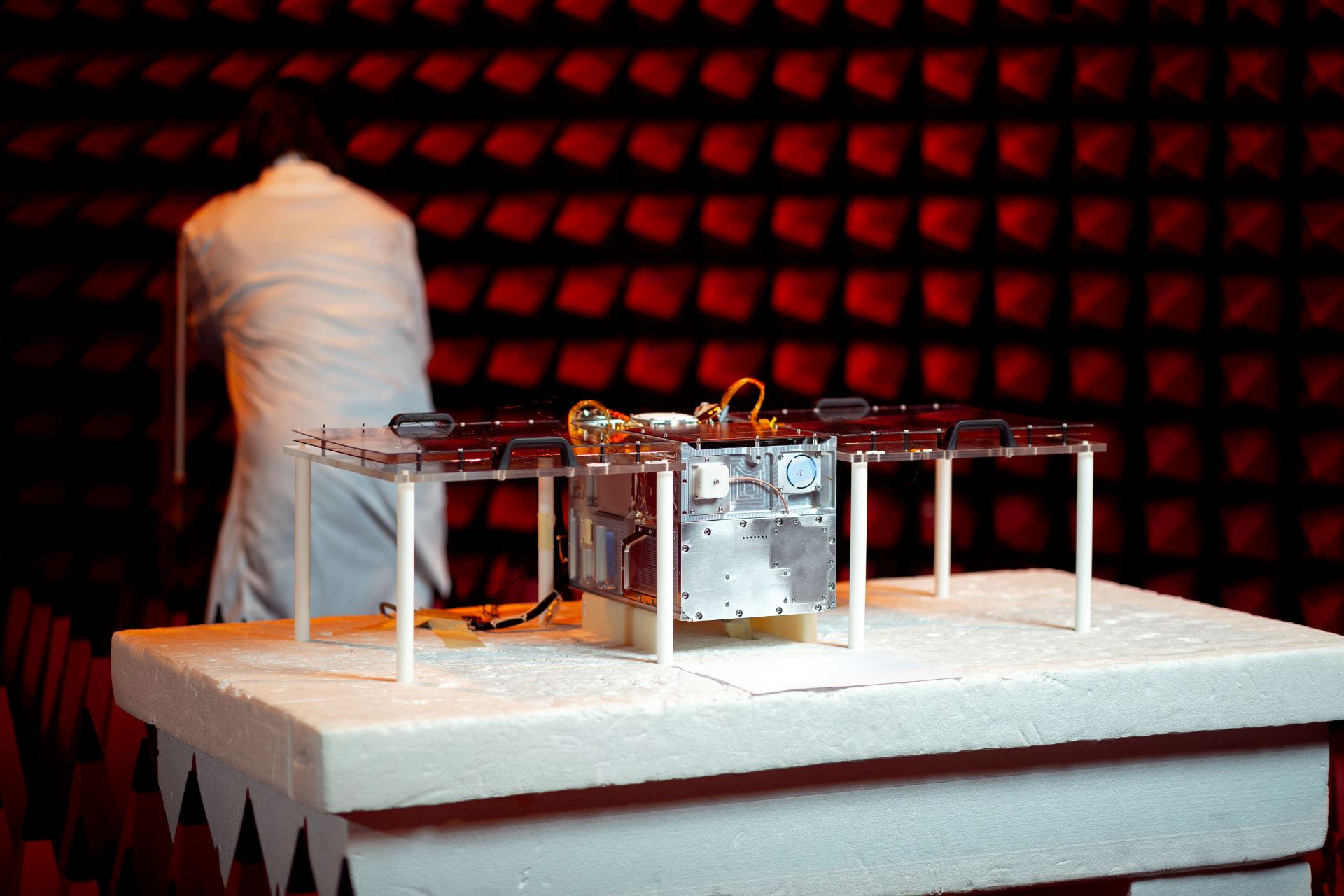

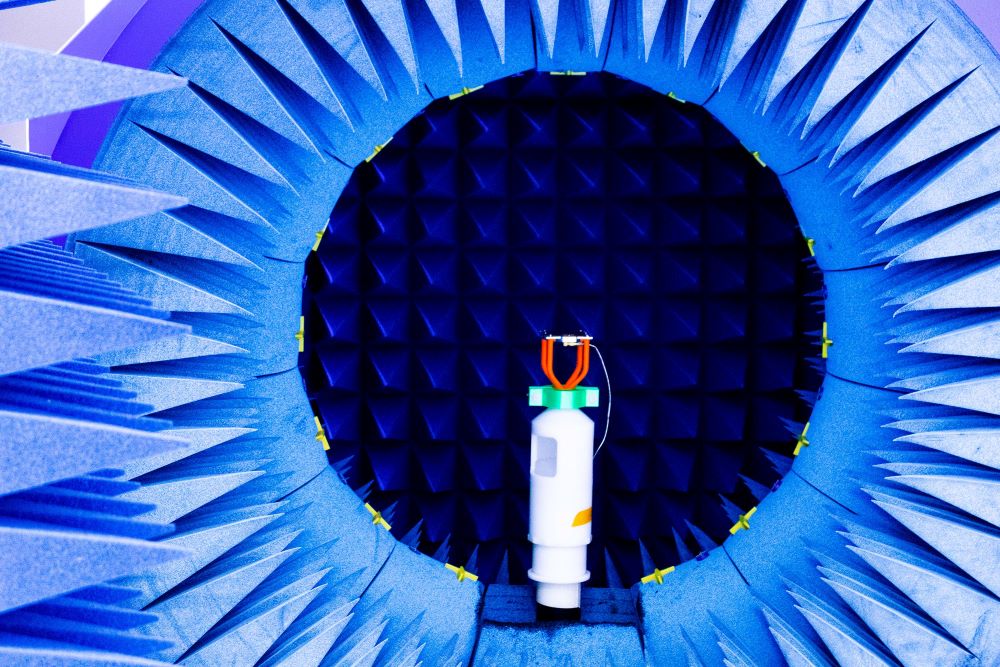

The TRR is a crucial phase where all test procedures, configurations, and criteria are thoroughly reviewed.

This ensures that the prototype is ready for the rigorous testing that will assess its suitability for space missions.

At the TRB stage, the results of the various tests are evaluated to confirm the antenna’s performance and readiness for production.

Here, any findings that could affect the system’s reliability or performance are addressed.

Industry-Leading Tools and Software

Utilizing these tools ensures that our antennas are designed with the highest level of precision, reliability, and accuracy. These are industry-standard platforms known for their reputation and specialization in their respective fields.

3D electromagnetic (EM) simulation software for designing and simulating high-frequency electronic products such as antennas, antenna arrays, RF or microwave components, high-speed interconnects, filters, connectors, IC packages and printed circuit boards.

World’s leading electronic design automation software for RF, microwave, and high-speed digital applications.

High-performance 3D EM analysis software package for designing, analyzing and optimizing electromagnetic (EM) components and systems.

Dedicated software for reflector systems, enabling fast and accurate analysis and design of the most advanced reflector antenna systems.

Esteemed for its specialized quasi-periodic and exact analysis algorithms, indispensable for complex reflector antenna designs.

Ansys Mechanical is a best-in-class finite element solver with structural, thermal, acoustics, transient and nonlinear capabilities to improve your modelling.

A platform for engineering simulation that allows for integrated workflows, aiding in the multi-domain interaction required in advanced antenna design.

A 3D modeling software renowned for its user-friendly interface and powerful capabilities, allowing for fast and efficient geometry preparation that streamlines the design process.

Your Partner in Project Success

Beyond designing industry-leading antennas, our team of experts is committed to guiding our customers throughout their projects. From project management and technical advice to co-development and co-creation, we are here every step of the way to ensure your mission’s success. Our engineers and project managers are available to answer any questions, resolve challenges, and turn visionary ideas into reality.

Resources

How Can We Help?

We look forward to hearing from you