Industrialization:

Transforming Innovations

into Scalable Solutions

Our Commitment

to Excellence

Beyond methodologies and philosophies, what truly sets Anywaves’ industrialization process apart is an unyielding commitment to excellence at every level. We don’t just aim for high-quality end products; we strive for perfection in every single element that contributes to making them.

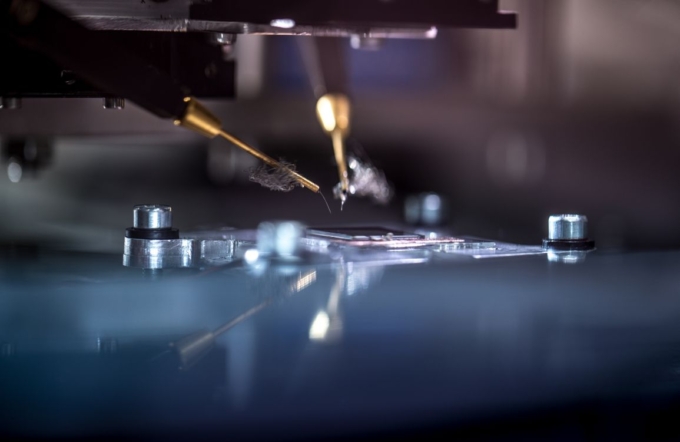

Our selection process for raw materials is rigorous. We partner with trusted suppliers who share our dedication to quality, ensuring that the foundational elements of our antennas meet or exceed industry standards.

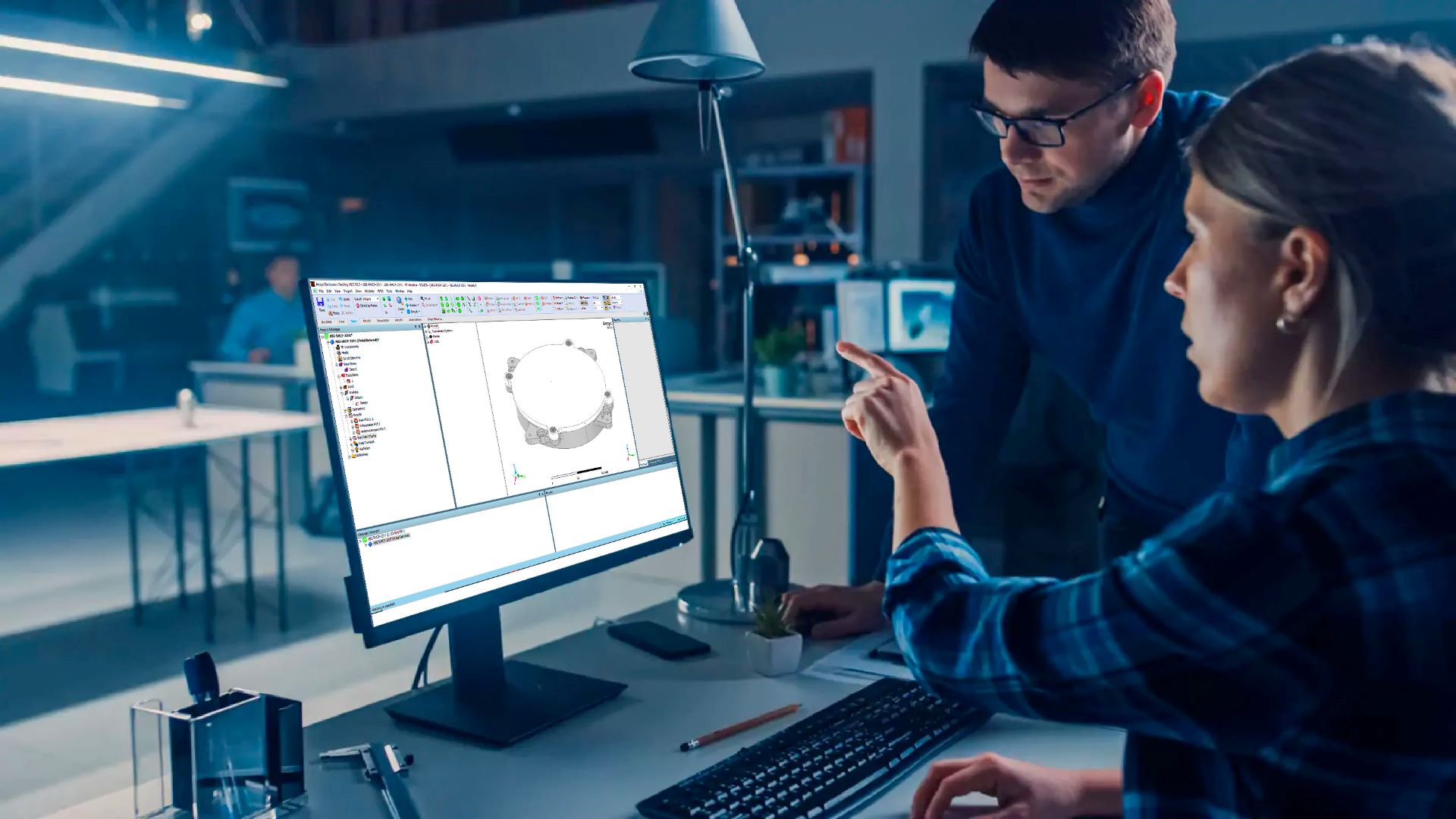

Adopting best-in-class manufacturing practices, we continually invest in state-of-the-art machinery and professional development for our workforce. This ensures that each step of the production process is optimized for accuracy, efficiency, and reliability.

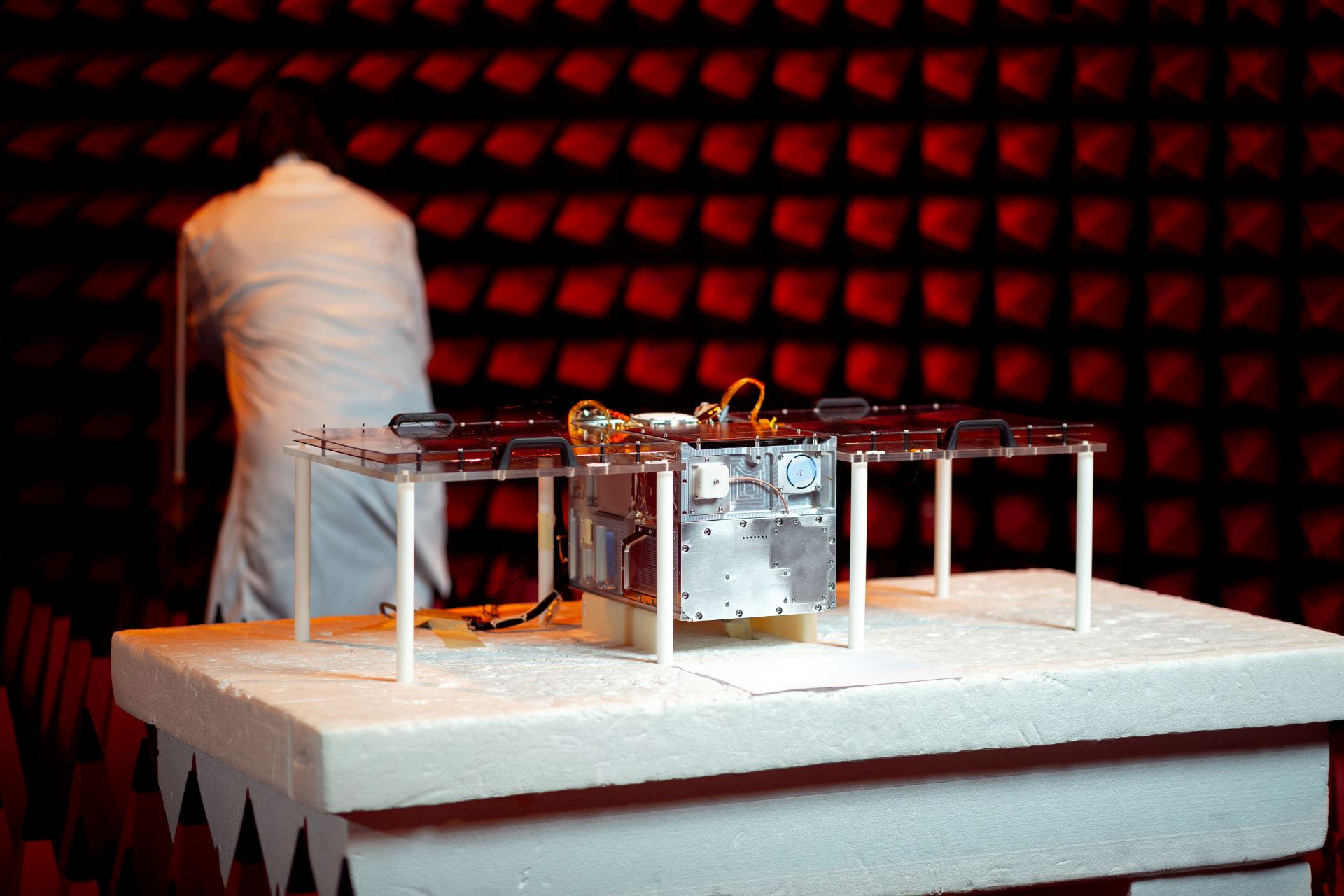

We have robust quality assurance protocols in place. These include automated and manual checks at different stages of production, and they extend far beyond standard requirements.

We believe that our rigorous approach to quality assurance serves as the final, critical safeguard, ensuring each product we ship lives up to the Anywaves standard of excellence.

By holding ourselves to these elevated standards, we aim to not just meet but exceed customer expectations, solidifying our position as a leader in space antenna solutions.

Continuous Improvement

& Process Optimization

In the fast-paced environment of space antenna technology, standing still is not an option. At Anywaves, we maintain a culture of continuous improvement to keep us ahead of the curve. Our industrialization process is a dynamic one, not a static blueprint.

Here’s how we ensure ongoing optimization:

We leverage real-time data to monitor performance indicators across our manufacturing and design processes. This allows us to quickly identify bottlenecks and areas for improvement.

Our team is our most valuable asset. Ongoing training programs ensure that they are always up-to-date with the latest industry practices and technologies.

We actively seek and incorporate feedback from our clients, using their insights to refine our processes and products.

As new technologies emerge, we assess their potential applications in our industrialization process, incorporating those that offer tangible improvements in efficiency, quality, or scalability.

We are constantly looking for ways to eliminate waste and streamline operations, all while maintaining the high quality for which our products are known.

Resources

How Can We Help?

We look forward to hearing from you