Innovation at Anywaves:

Pioneering the Future

of Space Antenna Technology

Our Innovation Process

Our journey begins with exhaustive research, market and competition analysis. We keep our finger on the pulse of industry trends, emerging technologies, and advancements in electromagnetic applications.

Through collaborations with academia, participation in scientific tradeshows and specialized industry research, we make sure we’re always a step ahead to be able to answer to all of our partners and customers requests.

It is specifically important to us to work closely with our suppliers in order to develop innovative and state-of-the-art antennas solutions.

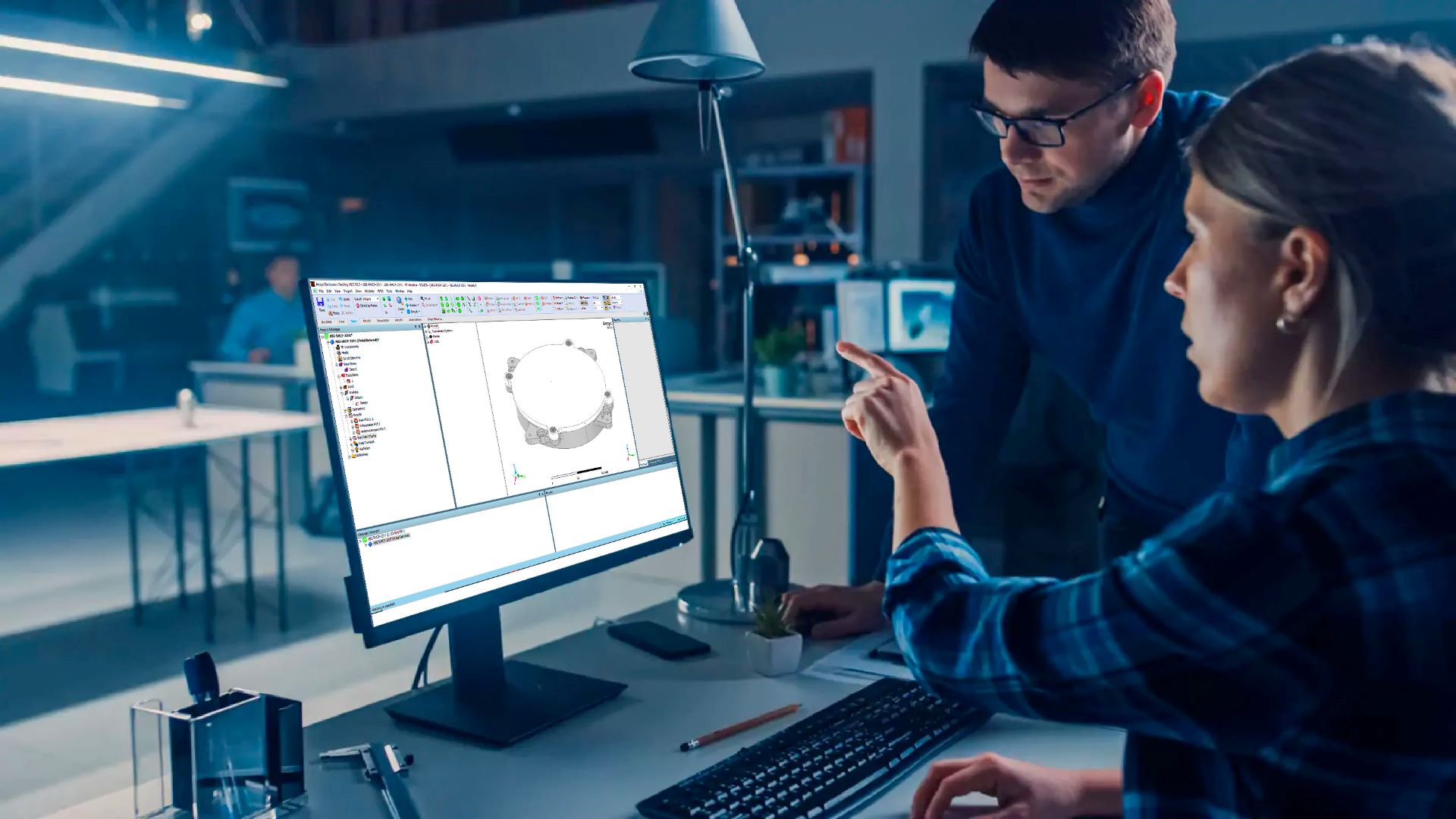

Informed by our research, our engineers initiate the conceptualization phase, exploring novel design geometries, and antenna architectures that meet specific customer requirements.

Our engineering team is composed with Radio-Frequency experts and Mechanical and Thermal specialists. Their knowledge combination is crucial to find the most performing and relevant solutions.

In addition, multiple iterations and multi-physic simulations ensure that we settle on the most optimal design.

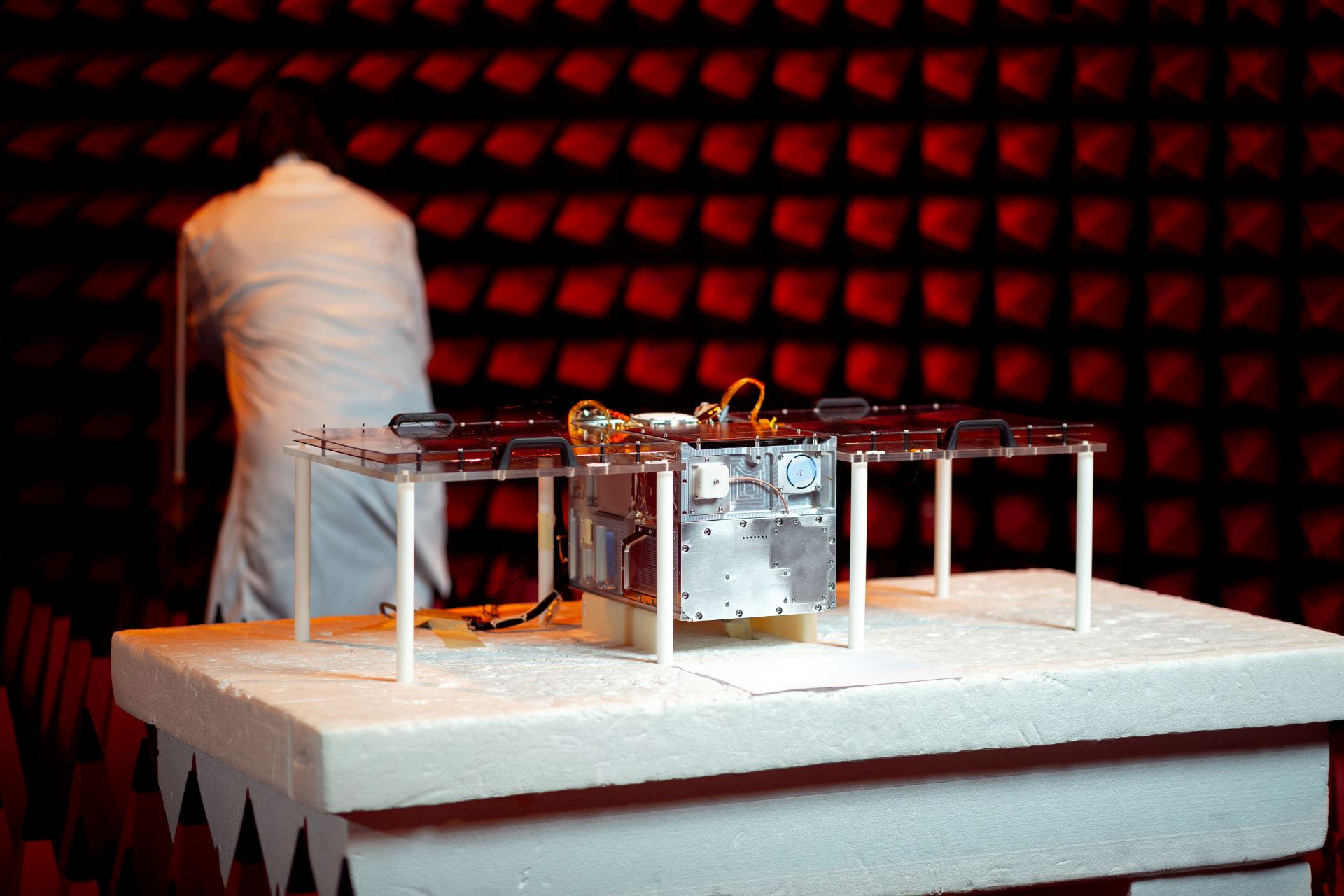

Once the concept is crystallized, we move into prototyping. Using state-of-the-art manufacturing techniques, we bring the concept to life and subject it to rigorous testing in simulated harsh conditions— vibration, shocks and extreme temperatures—to ensure our antennas can withstand the unique challenges posed by the space environment.

The full details of every test performed on our antennas are available on our Testing Process page.

The final phase involves in-flight validation with strong partners and customers.

Only upon successful validation do we initiate full-scale production, equipped with the assurance that our antennas meet the highest standards of reliability and performance.

Our Latest Innovations

As a testament to our dedication to cutting-edge design and technological advancement, we’re proud to showcase our most recent innovative products that not only meet but exceed industry standards.

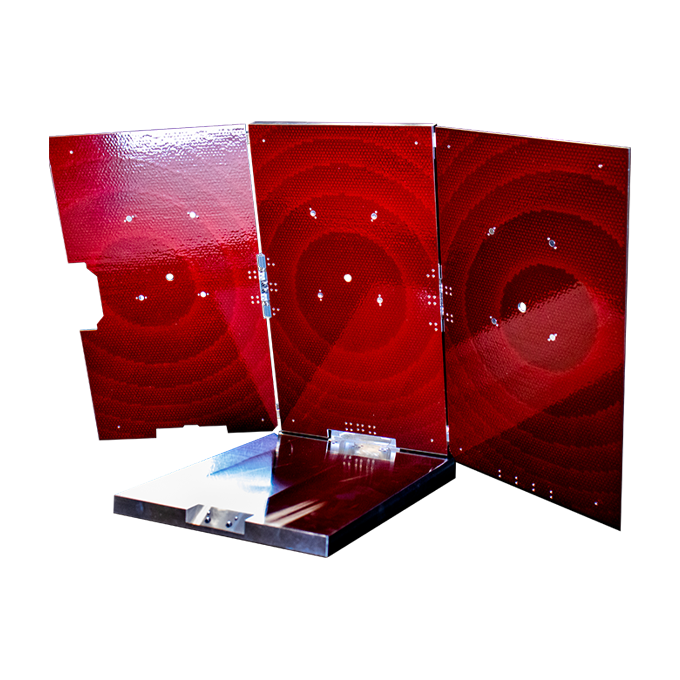

Our Reflectarray Antenna revolutionizes advanced communication systems in space, particularly for small satellites requiring high-data rate telecommunications and long-distance connections.

Unlike traditional parabolic reflectors, this technology uses flat, foldable panels for easy storage and deployment, making it ideal for space-limited environments. The panels offer precise local phase control of reflected radio frequency (RF) waves, ensuring optimal performance. Enhanced with robust structural design and passive thermal control, the antenna operates across a wide frequency range from X to Ka bands.

Custom-made upon demand, it is a highly versatile solution for missions ranging from Earth to interplanetary destinations like Mars.

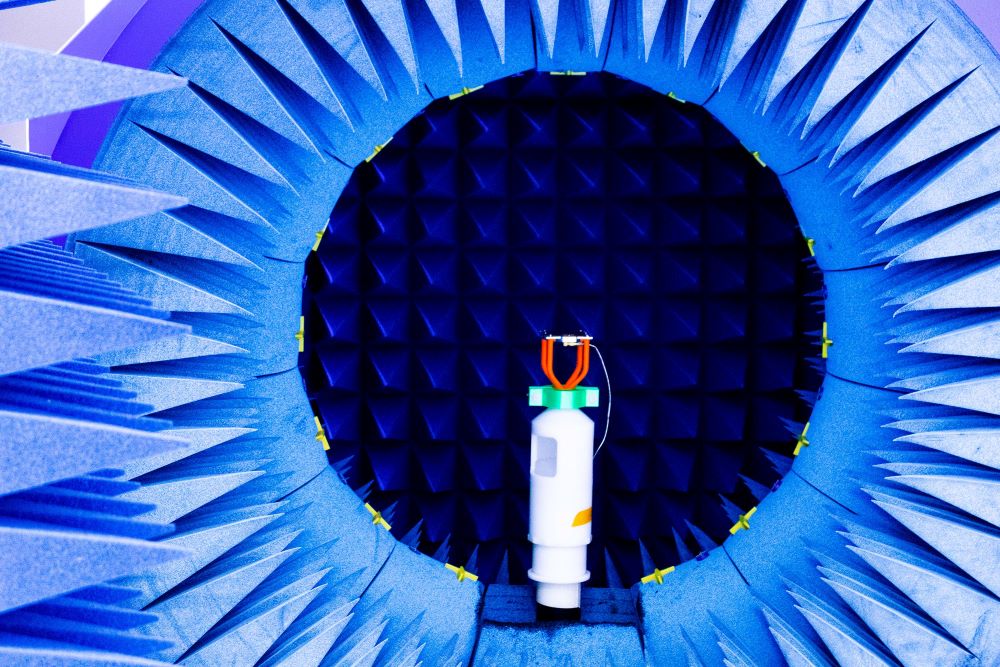

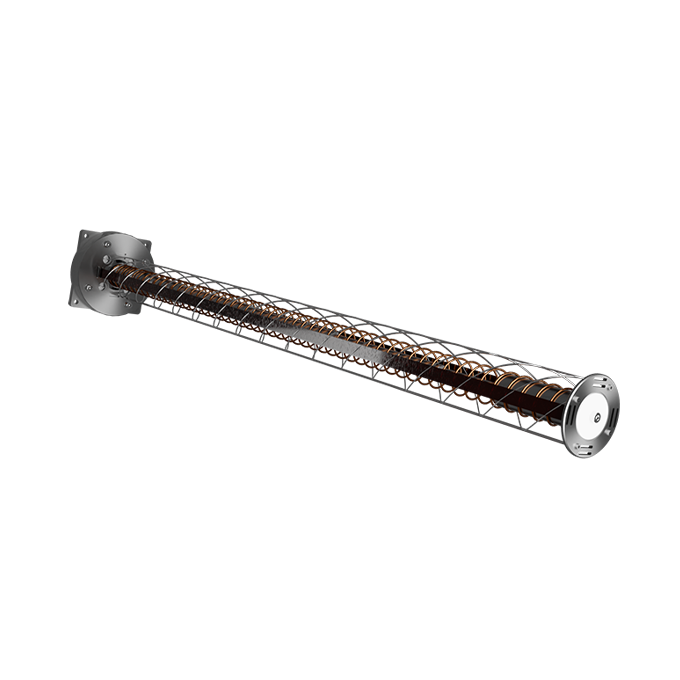

Our Quadrifilar Helix Antennas are specialized for space applications that demand a consistent and reliable isoflux radiation pattern, making them perfect for data transmission, LEO-PNT, and IoT applications.

Available in both deployable and fixed versions, these antennas provide a uniform RF energy distribution, ensuring high-quality signal connectivity between satellites and ground stations.

For space-constrained situations, our deployable versions offer mast-based technology with a superb stowed-to-deployed ratio and operate across UHF to S-band frequencies. Engineered to meet stringent space standards, they undergo rigorous thermal and mechanical tests.

Custom-made upon demand, our antennas can be tailored to your specific needs, setting a new standard in versatility and reliability.

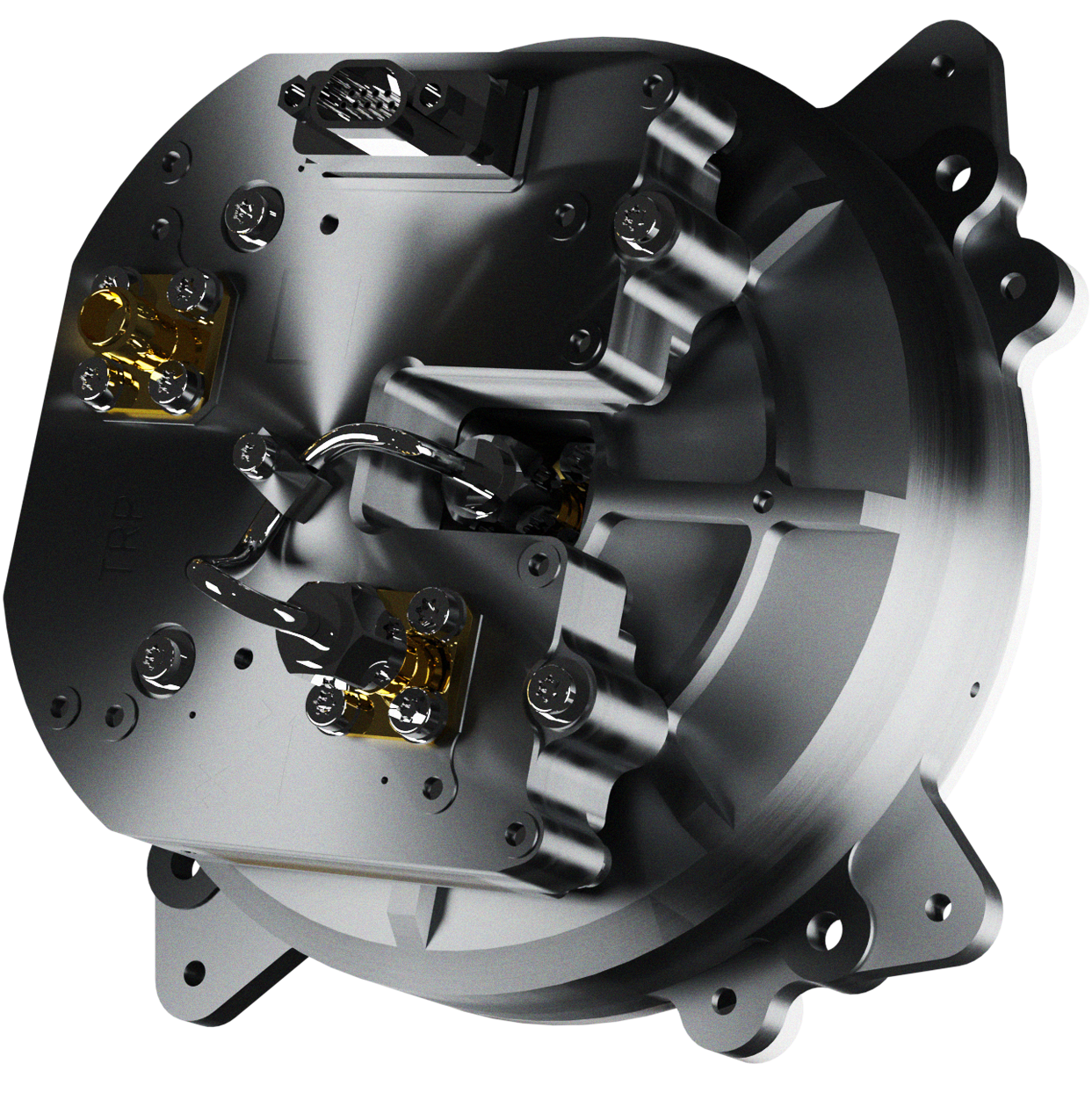

Our GNSS All-bands antenna has already proven to be the perfect solution for precise satellite navigation. It covers all GNSS constellations simultaneously with its very stable phase center and circular polarization.

This offers excellent signal stability, ensuring no signal blackouts occur even if one GNSS constellation breaks down. To reduce cable losses for your navigation and positioning link, we propose an integrated solution of our antenna with an active card comprising low-noise amplification and filtering.

This solution ensures the best compatibility and performance of your GNSS receiver for your satellite.

Resources

How Can We Help?

We look forward to hearing from you