Other news

What Makes a Good Space Engineer Today? Skills, Mindset, and the NewSpace Context

Read more

What is Antenna Gain in Satellite Communications? (Explained simply)

Read more

For decades, space antennas have been designed with orbit in mind. Low Earth Orbit, geostationary orbit, lunar orbit — these environments are well understood, and antenna systems have been optimized accordingly. But the next frontier in space exploration isn’t just above the surface — it’s on it.

From lunar landers to Martian rovers and sample-return missions, we’re seeing a steady shift toward planetary surface operations. These missions bring valuable science, support future crewed exploration, and test technologies that will one day enable long-term off-Earth infrastructure. But they also introduce a very different set of constraints for spacecraft systems.

Thermal extremes, mechanical shocks, dust, regolith, and microgravity — these aren’t edge cases anymore. They’re central design drivers. And for critical systems like antennas, which need to operate reliably in exposed, unpredictable conditions, the transition from orbit to surface isn’t just a change in altitude — it’s a change in mindset.

In this article, we explore the environments, mission types, and design implications that come with the rise of planetary surface exploration — and what it means for engineers building the systems that make those missions possible.

Over the past two decades, space exploration has undergone a quiet but significant shift. While orbital missions continue to deliver valuable scientific and commercial returns, an increasing number of agencies and mission planners are directing their attention — and investment — toward planetary surfaces.

This growing interest in surface exploration marks an important evolution in mission architecture, system design, and environmental requirements. Whether targeting the Moon, Mars, asteroids, or small moons like Phobos, these missions demand new capabilities — and new ways of thinking about spacecraft systems.

For decades, orbital missions have played a central role in exploring our solar system. They’ve mapped planetary surfaces, analyzed atmospheres, and delivered critical scientific insights from a safe distance. But while orbiters provide valuable data, they can only observe.

Surface missions do more.

Rovers, landers, and static platforms allow us to interact directly with extraterrestrial environments. They can drill, scoop, analyze, and measure in ways that orbiters simply can’t. As a result, surface exploration is gaining ground — not as a replacement for orbital missions, but as a vital complement to them.

Several mission types now rely on surface assets:

Planetary surface missions used to be the realm of just a few national space agencies. But that’s changing fast.

Today, surface exploration is a much more collaborative and dynamic effort — with government programs, commercial ventures, and hybrid partnerships all contributing. Some are leading full missions; others are developing key systems or delivering scientific payloads. The result is a growing mix of actors, each bringing different timelines, expectations, and integration models to the table.

And for teams building spacecraft subsystems — like antennas — that means designing for a wider range of platforms, environments, and technical cultures than ever before.

Some of the most ambitious surface missions are still being driven by government space agencies — often working together or with industry.

These agencies still set many of the standards when it comes to environmental qualification, thermal constraints, and comms architecture — and their missions often serve as anchor points for broader collaboration.

On the commercial side, there’s been a real acceleration.

Other industrial players — like Hemeria, Airbus, or Thales Alenia Space — are also moving into surface mission roles, sometimes through technology demonstrations or as subsystem suppliers. Many of them bring heritage from satellite programs, but are adapting fast to the demands of surface operations.

The reality today is that very few missions are built by just one team. Most are international, multi-contributor efforts — with different players responsible for different parts of the architecture: one agency for the orbiter, another for the lander, a private company for payload delivery, and yet another for mission ops.

That brings benefits — more flexibility, more innovation, more access to expertise. But it also introduces complexity.

It’s a more fragmented but also more flexible way of building missions. As more of them touch down on the Moon, Mars, and other planetary bodies, the shift from orbit to surface isn’t just changing how we explore — it’s changing how we build spacecraft.

In such environments, interoperability, interface compatibility, and standardized performance benchmarks are critical. Antenna systems — often small in size but vital in function — must be designed for seamless integration across diverse mission architectures.

But designing for the surface isn’t just about fitting into a larger system. It’s about surviving an environment that’s harsher, more unpredictable, and less forgiving than anything in orbit. That’s where the real engineering challenges start.

When you’re building hardware for orbit, you’re designing for a known set of conditions. You know the thermal cycles, you can plan for radiation exposure, and your spacecraft is unlikely to get covered in dust or slammed into a rock.

But when the mission lands — literally — all of that changes.

Surface missions bring a different set of challenges, and they impact everything from materials and mounting points to how systems are tested and qualified. Antennas, especially, sit at the front line. They’re exposed, they’re often mission-critical, and they don’t get a second chance.

Planetary surfaces don’t do “mild.”

On the Moon, for example, daytime temperatures can hit +120 °C, and then plunge to -150 °C at night. And lunar nights aren’t short — they last about 14 Earth days, plunging vehicles into extended periods of deep cold without sunlight. Surviving these cycles requires hardware that can handle not just the temperature extremes, but the long-duration thermal stress that comes with operating (or hibernating) through a full lunar night.

These swings can warp structures, stress solder joints, and throw off RF performance. Even small changes in shape can detune an antenna or shift its impedance. Thermal gradients across a single antenna element can be enough to cause problems — especially if materials expand or contract at different rates.

So it’s not just about surviving the cold or the heat. It’s about staying electrically stable through both — and through the transitions.

Most people think of launch as the harshest mechanical phase for spacecraft. But for landers and rovers, descent and impact can be just as brutal.

Depending on the landing strategy, you might see shock loads higher than launch — especially with passive systems, bounce-down landers, or impactors. Then there’s vibration from onboard actuators, moving arms, or wheels once the vehicle starts to operate.

Any hardware attached to the structure — antennas included — needs to handle:

If you’re mounting an antenna externally (which is often the case), that means accounting for mechanical strain in both design and qualification.

Ask anyone who’s worked on lunar or Martian missions: dust is one of the biggest long-term threats to hardware.

On the Moon, regolith is sharp, abrasive, and sticks to everything thanks to electrostatic charge. On Mars, it’s finer but equally invasive — and can cling to surfaces for months. On smaller bodies, dust behavior is even harder to predict because of microgravity.

Dust affects antennas in several ways:

This means materials, surface finishes, and even shape matter. Dust-exposed hardware needs to be designed for it — and tested accordingly.

With no atmosphere to filter things out, surfaces get hit with the full spectrum of space weather.

That includes:

For antennas, this can mean degraded performance, higher loss, or mechanical wear that creeps up over time. And when missions stretch from weeks to months or even years, those small degradations add up.

This is where design meets discipline. You can’t treat surface-bound hardware like orbital gear with a few tweaks. You have to test it for what it’s really going to face.

That means:

Also worth noting: mounting, cable routing, and integration can all impact antenna behavior. Testing in isolation isn’t enough — final performance depends on how and where it’s installed.

There’s no one-size-fits-all planetary mission. Some vehicles land and stay put. Others roam for months. Some deliver instruments and shut down after a single day. Others run on solar power for years. But whether it’s a lander, a rover, or a deployed sensor, once it’s on the surface, it has to deal with the environment as it is — not as planned.

This section looks at how different types of surface missions operate, what they’re exposed to, and how that affects system-level design decisions — especially for components that are external, exposed, or critical to communication.

Landers are built to deliver science where it matters — on the surface. They often don’t move once deployed, but that doesn’t mean their job is simple. Landing is mechanically aggressive, and staying operational afterward requires stable thermal, electrical, and RF performance in unpredictable terrain.

Common lander missions include:

These platforms deal with:

All of this must be anticipated in the design phase — and verified during qualification. Even something as basic as where an antenna is mounted can determine whether the vehicle can maintain its comms link post-landing.

Rovers add another layer of complexity: motion. These platforms don’t just land — they drive, stop, turn, and climb. That introduces mechanical loads and RF constraints that don’t exist for stationary vehicles.

Examples of rover-based missions:

For mobility systems, key design considerations include:

Maintaining consistent communication during motion means that everything — from structural damping to beam coverage — needs to be considered in context.

Rovers also challenge assumptions around orientation. An antenna that works well on a flat test stand might lose link margins entirely when the rover is pitched 20 degrees on a slope, or when a wheel lifts during obstacle traversal.

Not every surface mission is a full vehicle. Some payloads are delivered, deployed, and left to operate autonomously for long periods. Think seismometers, radiation sensors, weather stations, or small networked nodes designed for distributed science.

Examples:

These systems face slightly different challenges:

Antennas on these platforms may be small, but they can’t be an afterthought. Once deployed, there’s no adjusting them. If the system loses link due to thermal drift or environmental damage, that’s often the end of the data stream.

If you want a good example of how far surface exploration has come — and how complex it’s become — look no further than MMX, the Martian Moons eXploration mission led by JAXA.

MMX isn’t just another orbiter. It’s a hybrid mission that combines orbital science, surface operations, and sample return — all in a single flight. Its target is Phobos, the larger of Mars’ two moons, and its objectives are ambitious: map the surface, collect a sample, return it to Earth, and deploy a small rover to study the environment up close.

It’s a mission that blends everything we’ve talked about so far — multinational cooperation, demanding surface conditions, tight environmental constraints, and a systems architecture where even small components have to perform flawlessly across very different phases of flight.

Phobos is not Mars. It’s a tiny, irregularly shaped moon — about 22 kilometers wide — with almost no gravity and an escape velocity of just a few meters per second. There’s no atmosphere. No weather. But that doesn’t mean it’s an easy place to land.

In fact, surface operations on Phobos are uniquely challenging:

These factors make system design especially sensitive — from mobility to power management to communications. For something like a surface antenna, you can’t rely on stable ground orientation or long, uninterrupted windows. You have to assume movement, occlusion, and high exposure.

MMX is also a good example of how complex the engineering ecosystem around a surface mission can be.

With so many players involved, the integration effort is significant. Mechanical, thermal, and electrical interfaces all need to be defined early and tightly managed. Components — including comms systems — have to meet a shared set of environmental specs, test requirements, and data formats. And since the whole mission is flying on a single spacecraft, mass and power margins are tight.

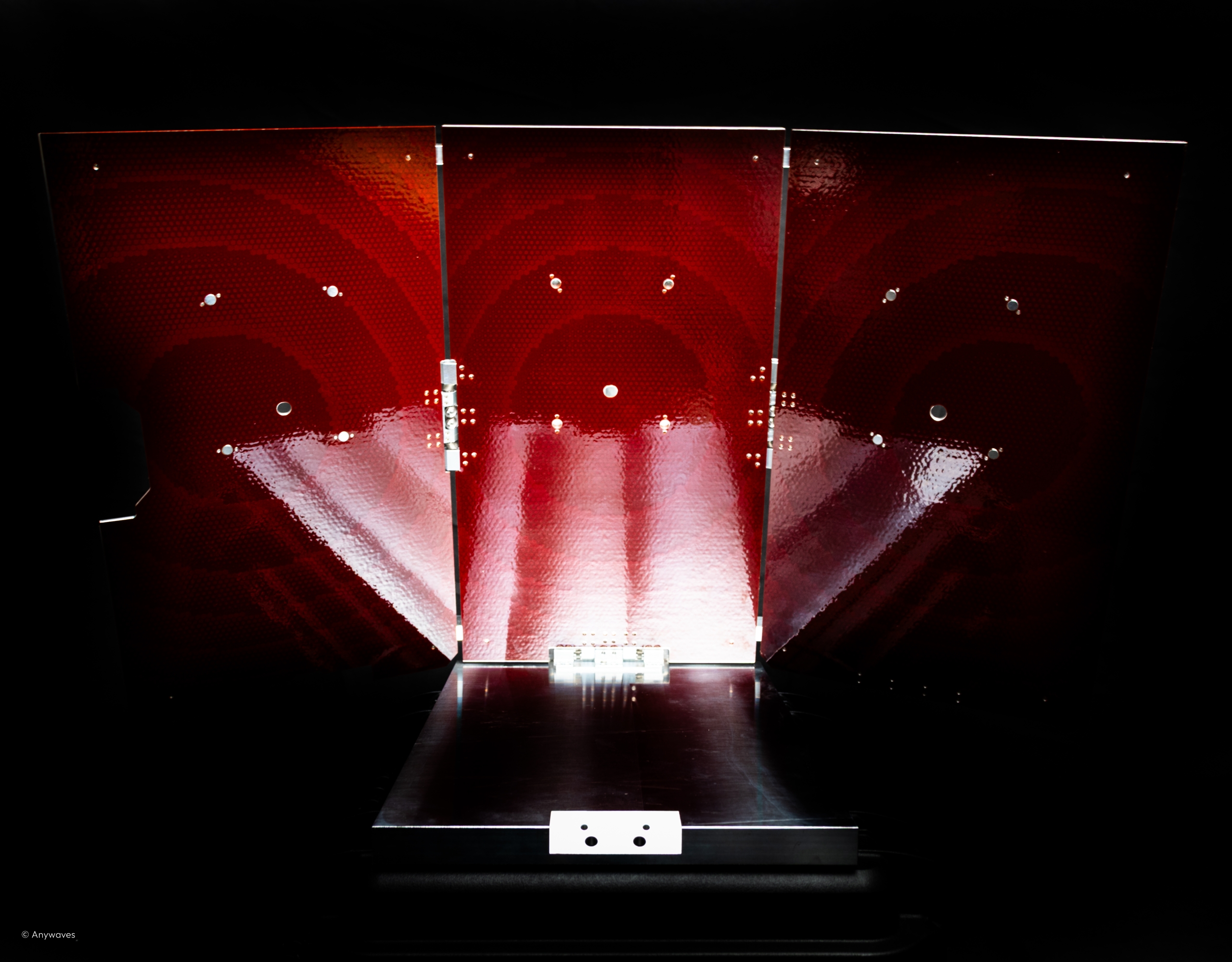

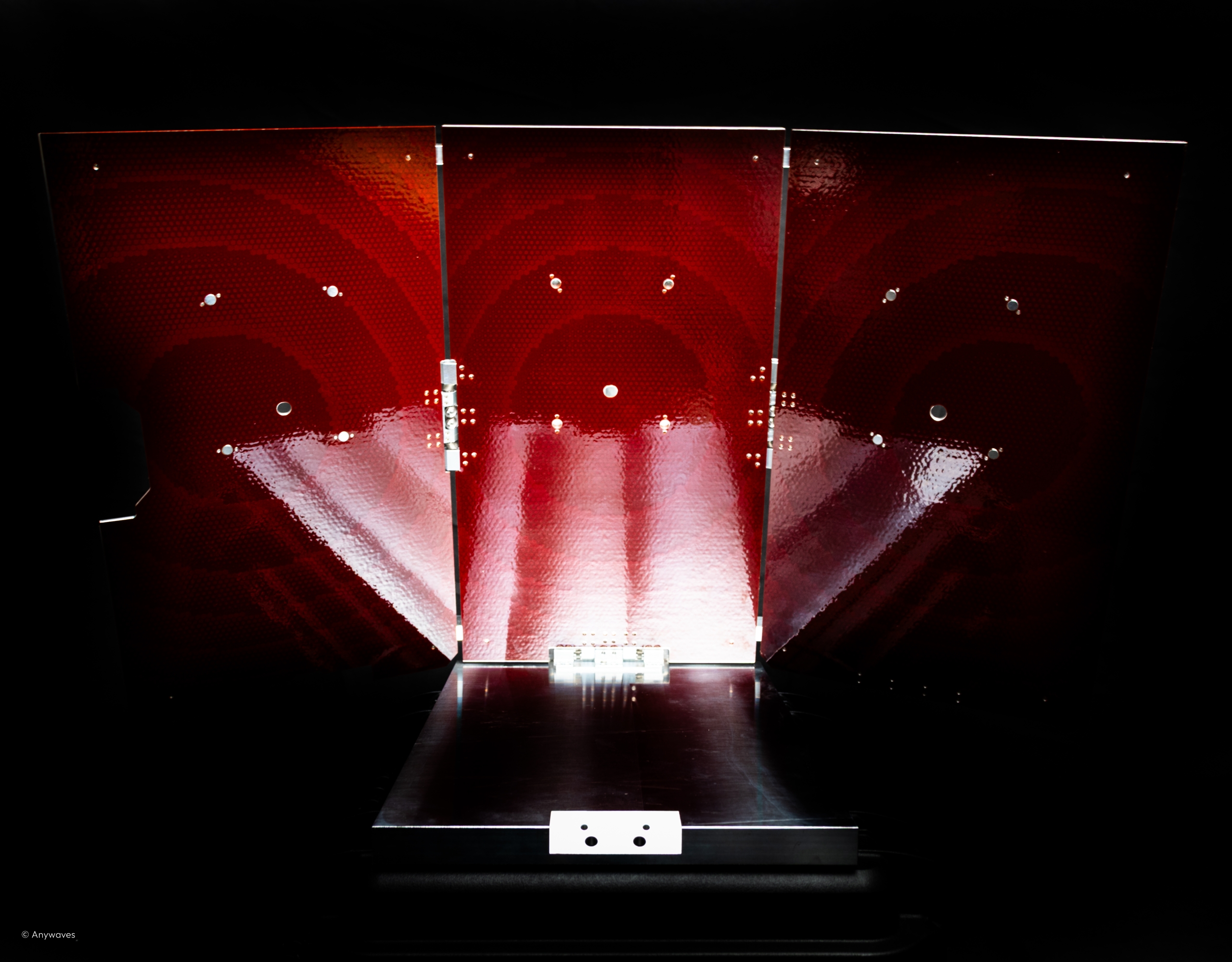

In this context, maintaining a stable communication link between the rover and the MMX orbiter is critical. That’s where the antennas come in. The small rover developed by CNES and DLR — just 25 kg at launch — will rely on a pair of custom S-band TT&C antennas to stay connected as it explores Phobos’ surface. Designed to operate in an extreme thermal and mechanical environment, these antennas had to be compact, lightweight, and rugged enough to survive both the landing shock and the microgravity surface conditions.

Because the rover may tumble or shift slightly after deployment — and can’t rely on traction to orient itself — the antenna system must offer stable, omnidirectional performance regardless of position. This guarantees that science data, housekeeping telemetry, and mission-critical signals can flow reliably during the rover’s brief but high-value mission.

It’s a small component on a small rover — but it plays a big role in keeping the surface segment of MMX connected, coordinated, and operational.

MMX is just one mission, but it’s part of a larger trend: surface platforms are getting more integrated, more complex, and more reliant on components that can work across multiple environments — orbit, descent, landing, and surface ops.

It’s also a reminder that planetary exploration doesn’t follow a standard playbook anymore. Every target — whether it’s the Moon, Mars, Phobos, or a near-Earth asteroid — brings its own physics, its own terrain, and its own communication challenges.

That’s why systems thinking matters. It’s not enough for individual components to work in isolation — they have to survive and perform in context. MMX makes that clear, and as more missions adopt similar hybrid architectures, this kind of thinking will only become more important.

Surface missions are pushing spacecraft systems into environments they weren’t traditionally designed for — and it shows.

Whether it’s a lander operating through one lunar day, a rover navigating Martian terrain, or a microgravity vehicle exploring the surface of a small moon, these platforms demand systems that are ready for the environment they’re in — not just the mission profile on paper.

For components like antennas, that means adapting to new conditions: dust, shock, variable orientation, thermal cycling, and tighter integration constraints. It also means rethinking how we test, qualify, and design for long-term stability in environments that don’t offer second chances.

Missions like MMX show what this future looks like: complex, collaborative, and full of unknowns. But they also show that it’s possible — when every component is designed not just to function, but to survive and perform on the surface of another world.

____________________________

At Anywaves, we’re not only capable of adapting our COTS antennas to surface platforms — we can also design products specifically for them.

Each mission is different. A static seismic station on the Moon doesn’t need the same antenna as a mobile Phobos hopper. That’s why we can offer:

Our design process begins with a detailed understanding of your mission profile, and ends with an antenna that’s flight-ready — and surface-capable.

If you have any question, we would be happy to help you out.