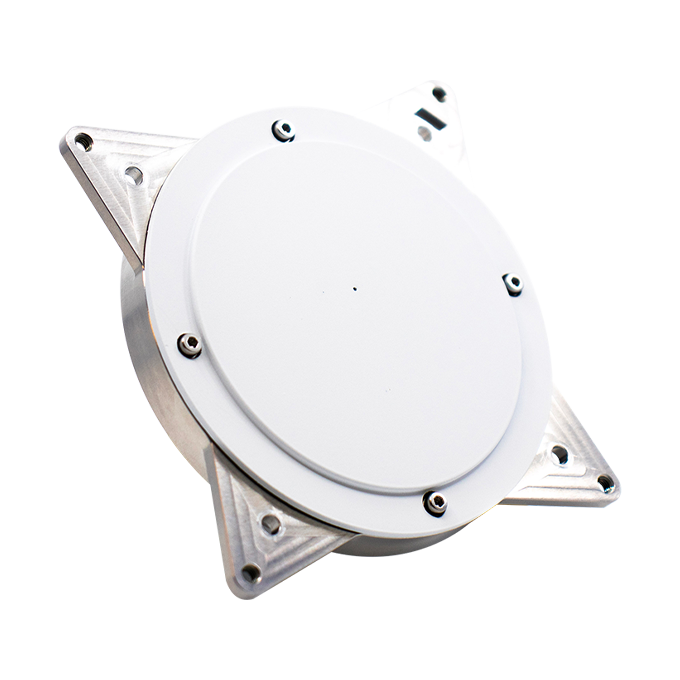

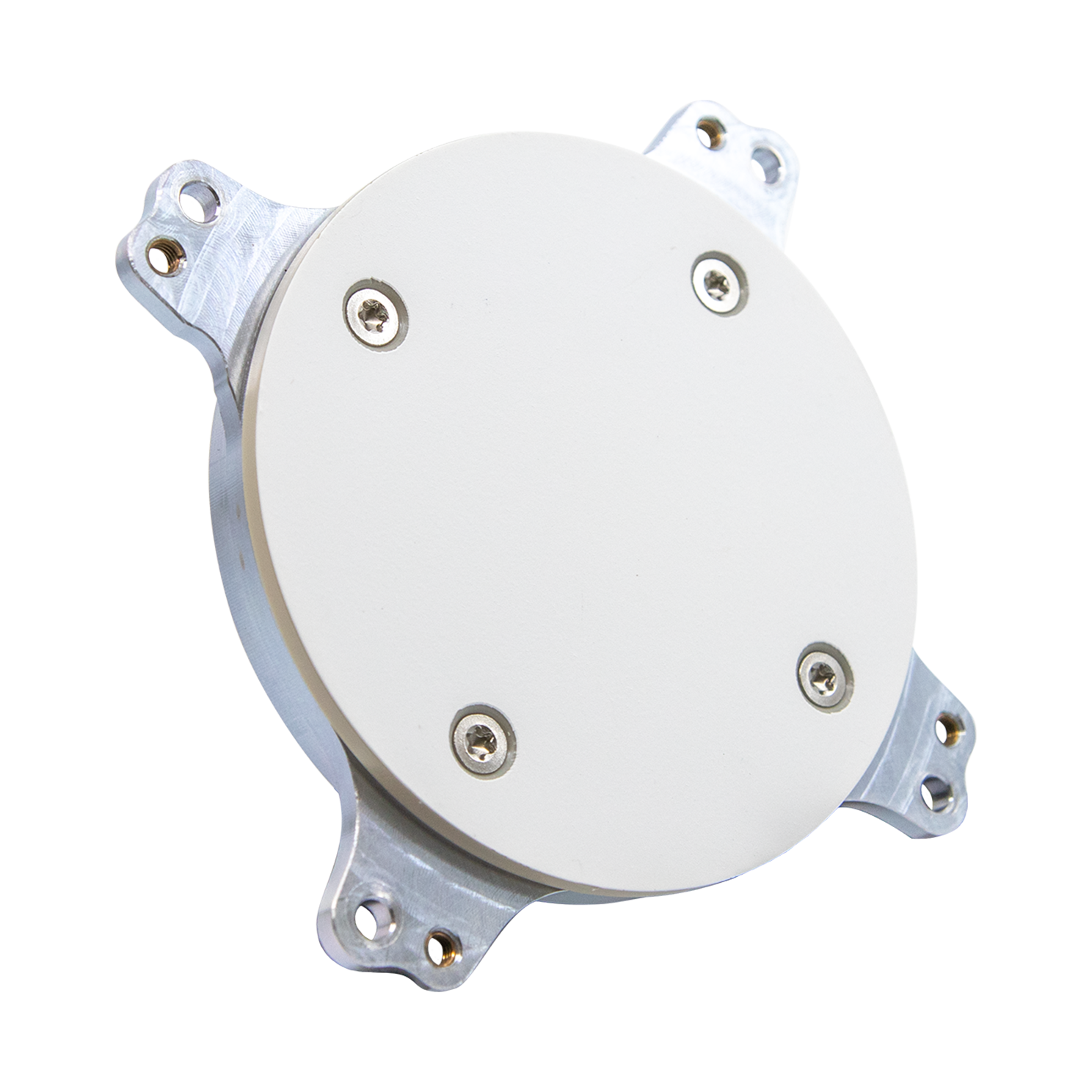

We offer a range of off-the-shelf antennas perfectly designed according to space standards as an answer to the satellites constellations market’s needs : TT&C, Data Downlink and GNSS.

We are also able to cover your spatial missions specific needs by developing custom antennas : high gain antennas (payload telemetry, inter-satellite link, telecommunications, etc.), wide band antennas (spectrum surveillance, GNSS, LEO PNT, etc.) or any other type of antennas and applications (integrated antennas, active antennas, etc.).

All of our antennas are available in two different versions: an engineering model and a flight model. Both have the same electrical performances as they use the same materials and processes. On flight models, we perform meticulous and rigorous acceptance tests.

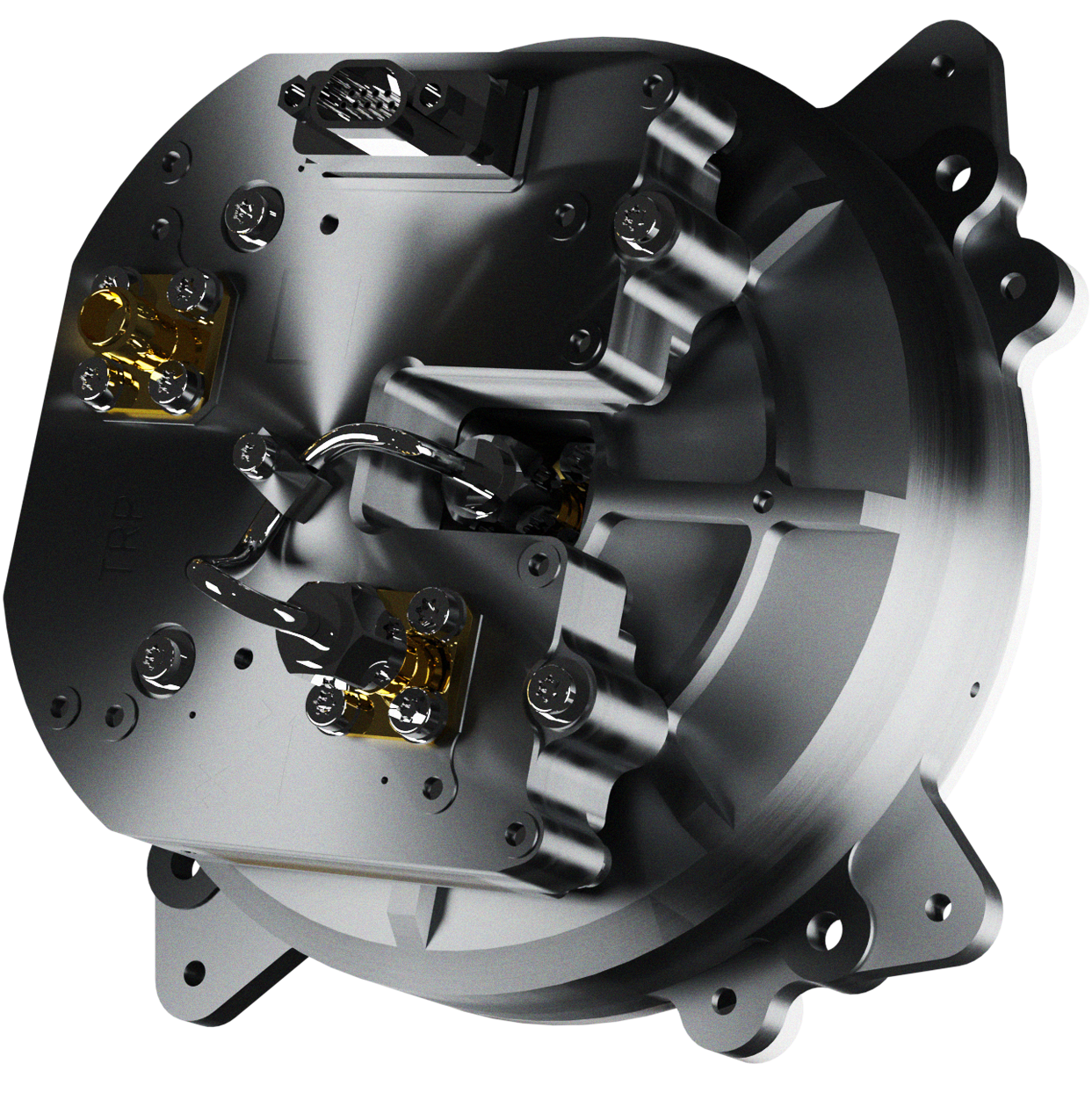

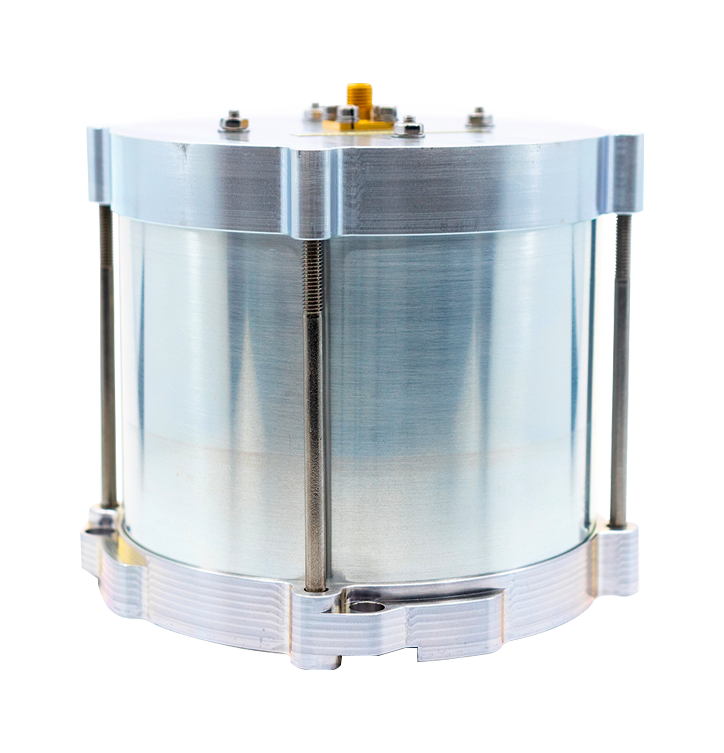

Telemetry, Tracking & Command (TT&C) Antennas

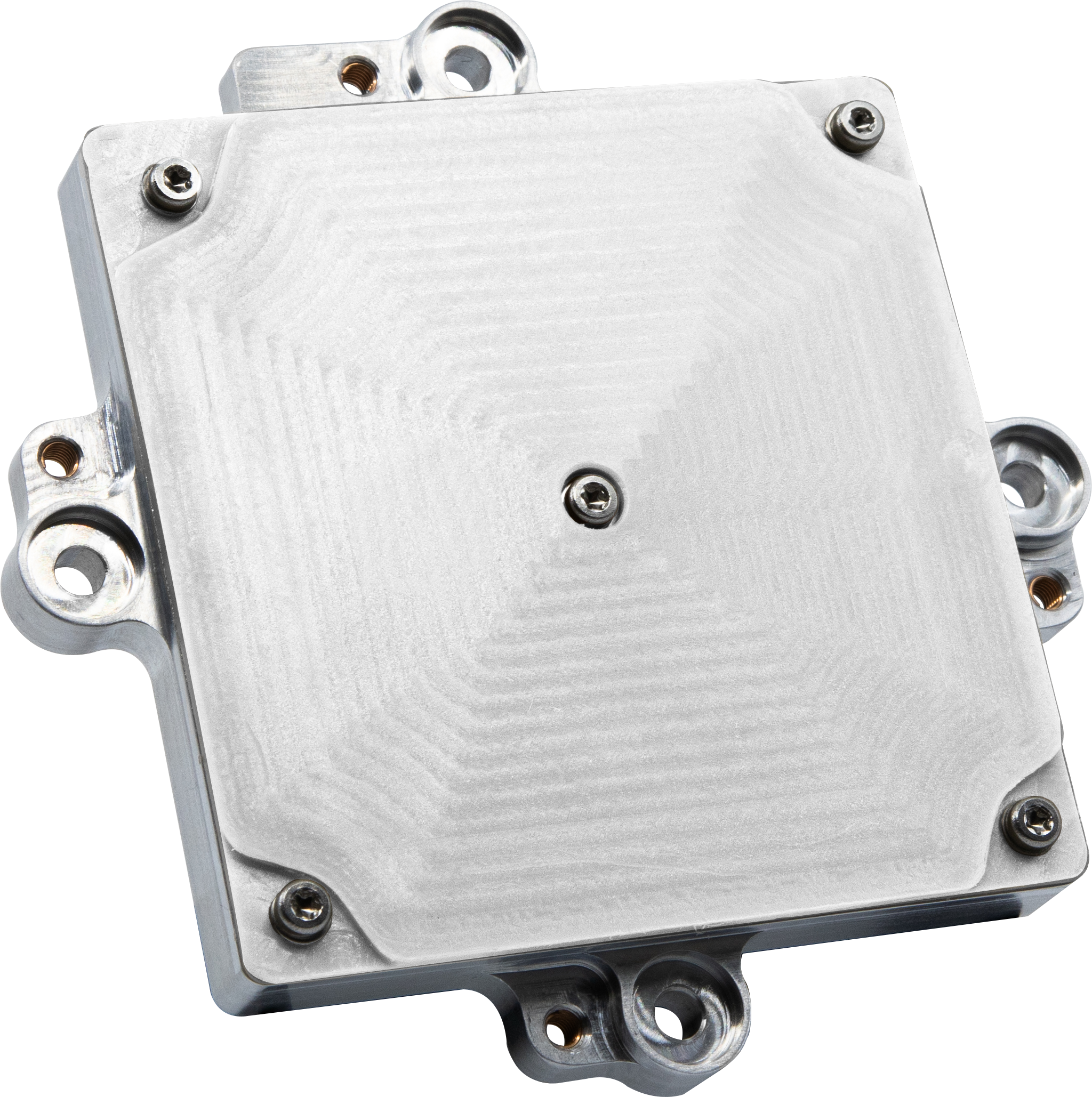

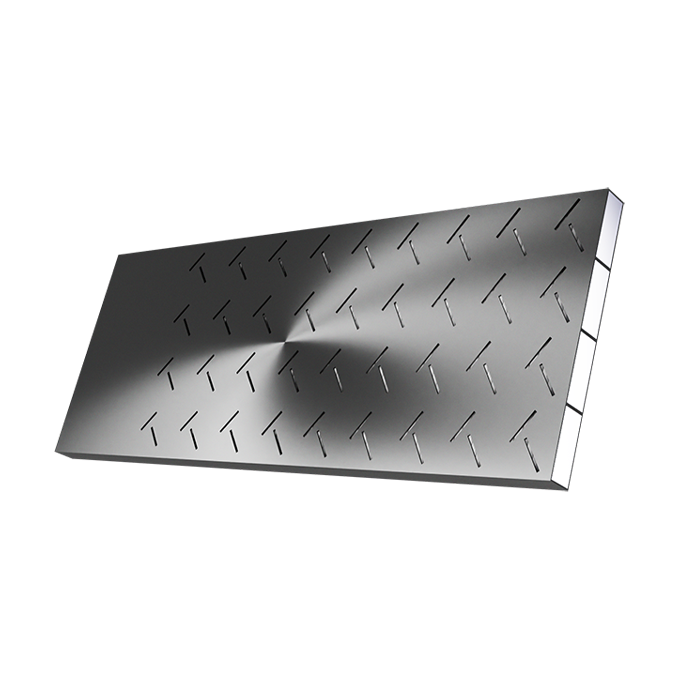

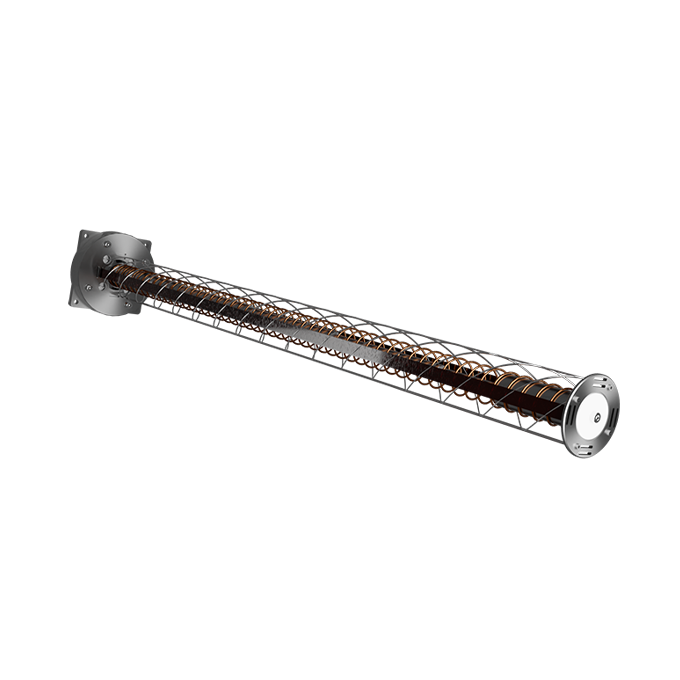

Data Downlink Antennas

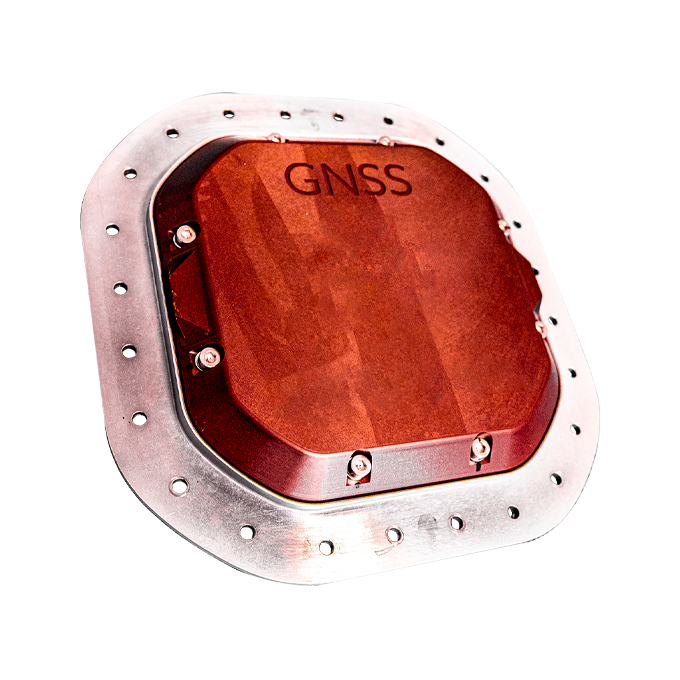

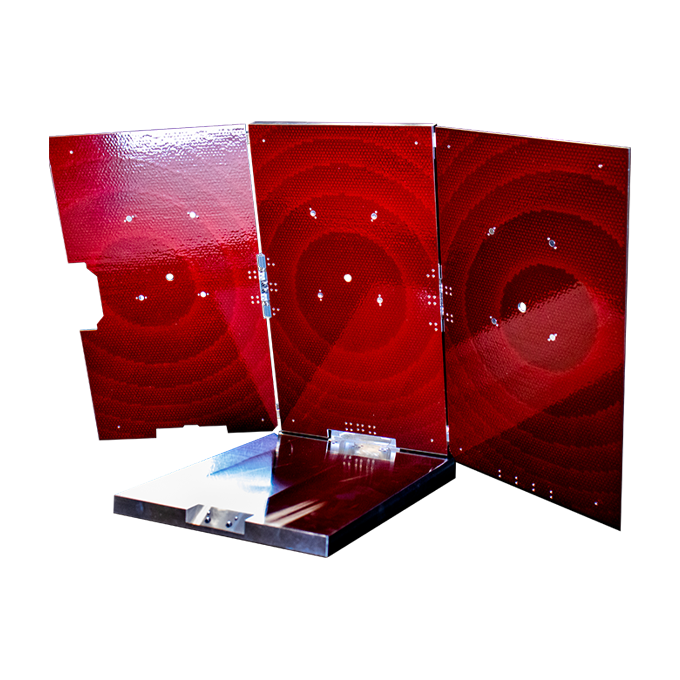

GNSS Antennas

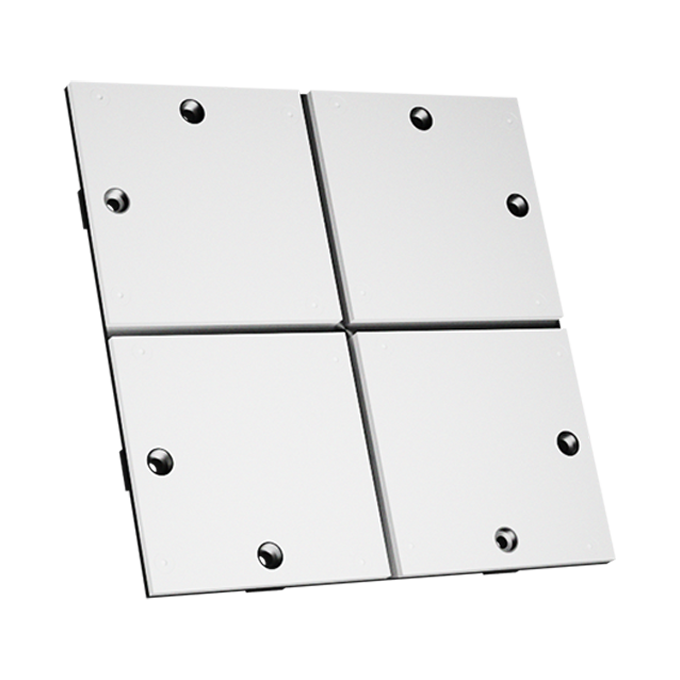

Launchers Antennas

Payload Antennas

Q&A

Engineering Models (EM) and Flight Models (FM) of antennas are nearly identical in terms of materials, processes, and electrical performance. However, acceptance testing is performed exclusively on Flight Models. Additionally, Flight Models of S-band TT&C, X-band Payload Telemetry, and GNSS All-bands antennas feature a special radome anti-ESD paint coating

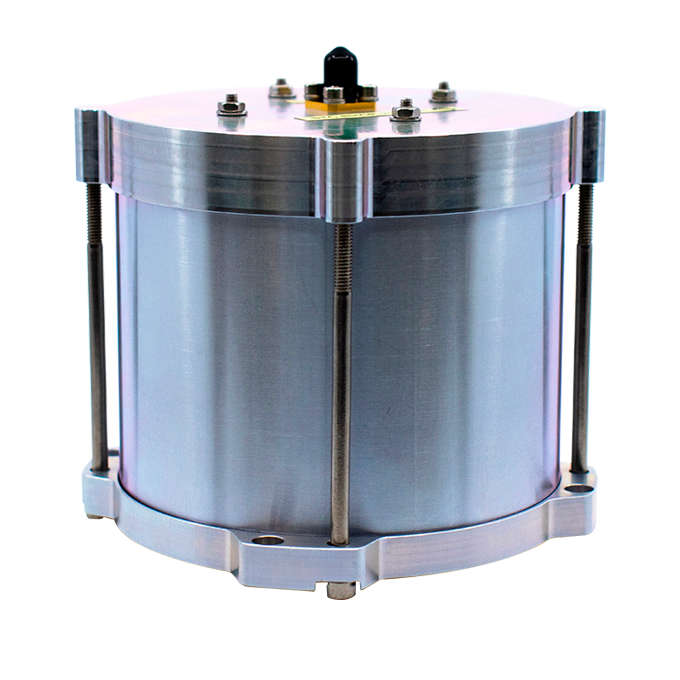

Our qualification testing process for antennas involves subjecting them to demanding tests to ensure their durability and performance in space conditions. These tests include functional measurements, random vibration, shock, vacuum thermal cycling, long thermal cycling. We also conduct power handling tests for transmission antennas and perform rigorous final inspections before concluding the qualification phase. For more detailed information on our testing process, don’t hesitate to contact us!

Our off-the-shelf antennas have been specifically designed and tested to withstand LEO (Low Earth Orbit) environment. If your mission will take place in another Orbit (MEO, GEO…), we can study if our COTS antennas can match your requirements. Otherwise, we can either adapt our antennas or build from scratch a dedicated custom-made product.

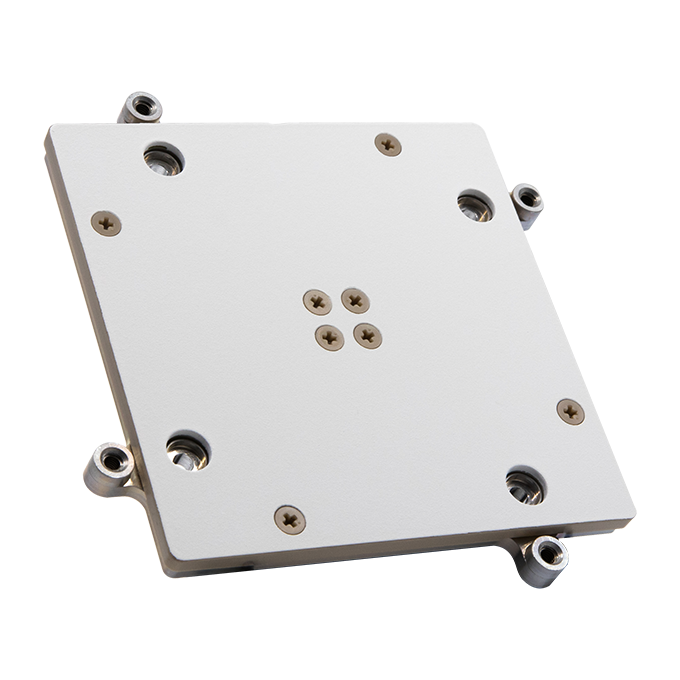

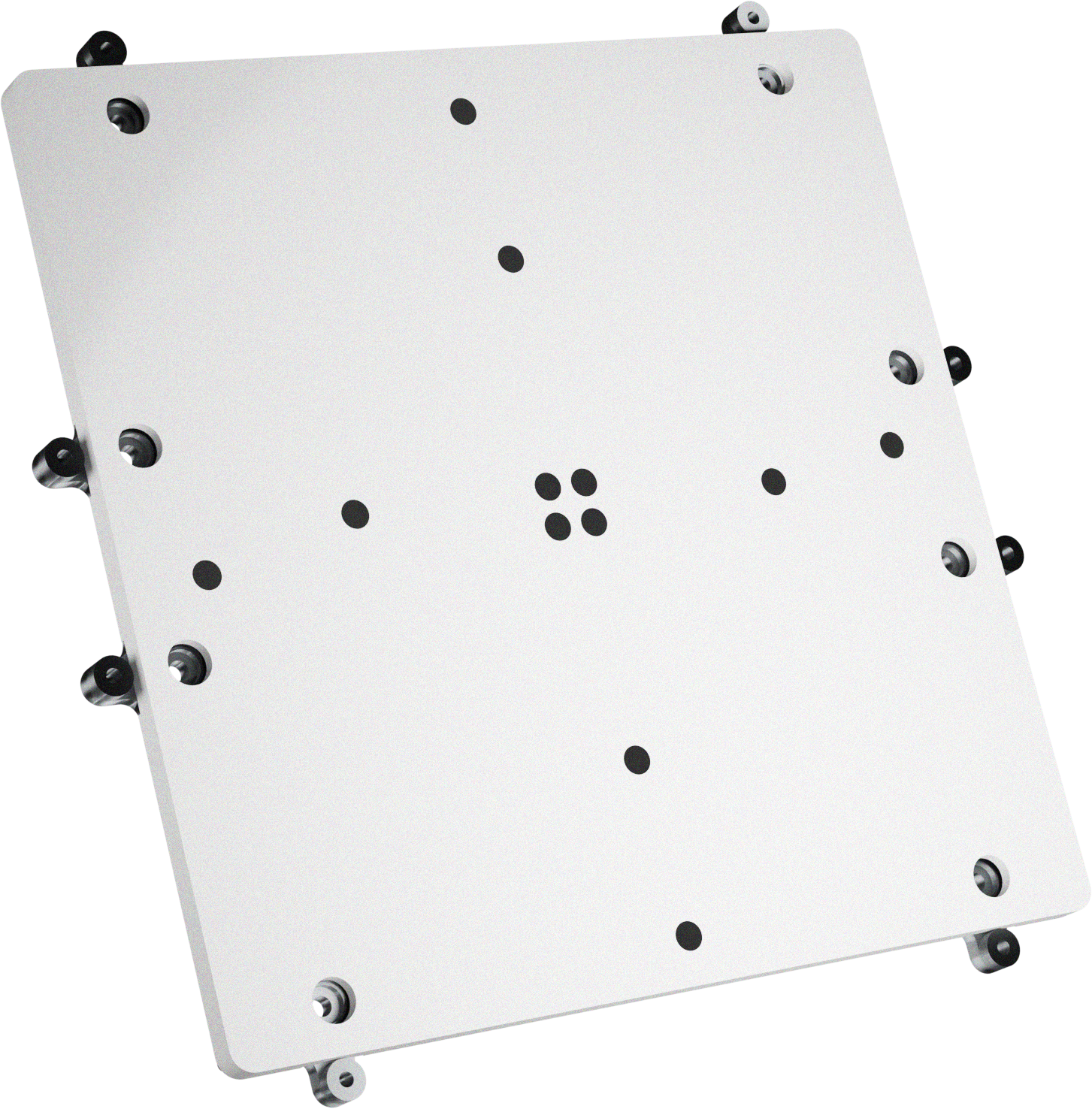

A test cap (or test hat) is a ground segment equipment which allows to perform an end-to-end RF test directly on your satellite. With this equipment, you will no longer need to perform RF tests in anechoic chamber. It will save you a lot of time and money!

To ensure the functionality and durability of each flight model delivered to customers, acceptance tests are conducted. These tests, while lighter than qualification tests, still involve an S-parameter test, random vibration test, and thermal cycling at ambient pressure. The process concludes with a final S-parameter test and an external visual inspection to guarantee the quality of the antenna.

There are several key factors that set ANYWAVES antennas apart as the best choice on the market. Firstly, our antennas are built using a proprietary manufacturing process that guarantees exceptional repeatability and short lead time. Secondly, they are highly adaptable, covering a wide range of frequencies and applications. Additionally, ANYWAVES antennas are lightweight and compact, making them ideal for space missions and other demanding applications. With unmatched reliability, quality, and performance, ANYWAVES antennas consistently deliver outstanding results, making them the top choice for discerning customers in the industry. We have written a full article to help you understand the specificities of our antennas and design process, you can read it here.

Absolutely! At Anywaves, we understand that choosing the right antenna can be challenging. Our team of experts is here to assist you. We offer personalized consultation services tailored to your specific needs. By understanding your requirements and applications, we can recommend the most suitable antenna from our extensive product range. Don’t hesitate to reach out to us, and we’ll be more than happy to guide you in selecting the perfect antenna solution.

All of our antennas are entirely designed and manufactured in France. Our French production suppliers have been carefully selected for their quality of service, their EN9100 certification and their spatial specialization. This allows us to ensure the highest standards of precision, reliability, and performance in every antenna we produce. By controlling the manufacturing process, we can closely monitor and optimize the quality at every step, resulting in antennas that meet the specific needs of our customers.

Contact

Us

How can we help you with your space antennas’ needs?